Project Galleries

| OUR PROJECT GALLERIES

CIR Industrial Automation has been providing human machine interface systems since 1986. The following project case histories demonstrate our ability to solve virtually any challenge we come up against.

Utilities Process Control HMI Application

• Dunkirk Glass

Created "Lumaglass" which when fractured always created sharp edges that were perfect for sand blasting. We created the control and the HMI to operate the mixing plant as well as the grinding plant. (The grinding and sizing are what you see in these screens.)

• Dunlop Tire ATV Tire Line

Created the control and the HMI to operate the utilities part of the tire making control. Included sumps and pumps. Was also the main data collection point for the steam and nitrogen usage for this process. Illustrates both data and trending of usage. Maintenance screens for motor runtimes and key set points.

• DuPont Corian

Inspection area for finished sheets of Corian. (Goes to sanding before shipping.) Sheets are inverted in the barrel and inspected. The sheets are graded and the servo-controlled hoist picks up the sheet and delivers to the Graded Stack. All stacks automatically adjust for height. Both control and HMI created by CIR. All control including suction cups controlled via recipe.

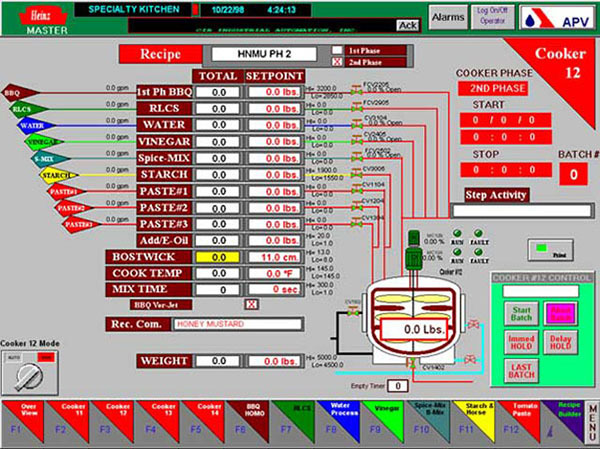

Food Processing HMI Application

• Heinz BBQ and Cocktail Kitchen

Features: completely recipe driven ingredients, mixing, PID controlled heating, and post processing. All control elements have bump-less crossover to Manual and back to Automatic. Pop-up templates for PID, Manual-Off-Auto, and Speed control. Maintenance screens for key settings and alarming criteria. Complete historical archives of mix data and retrieval tool. Shift and daily reporting.

Wastewater Treatment HMI Application

•Amherst Wastewater Treatment Plant

Complete automation of the waste treatment process; from influent to clean water effluent and "Pellet Process" or land fill of solids. Noteworthy is the graphical representation of the plant processes. Also the capture of fuel (methane gas) from the Digesters that is used to run the boiler, the gas operated pellet oven, or just out to a flare. All Gas volume data, produced and consumed, is collected for Day and Week. The historical data logging keeps data for a minimum of one year.

Acetone Filling Station PanelView Application

• Praxair Acetone Filling Station

A pilot project for worldwide applications of the acetone filling of Acetylene Cylinders. Note: Acetone is the sponge that absorbs Acetylene at elevated pressures and makes for stable transporting. Filling process includes the calculation of residual amount of acetone and acetylene so as to refill the appropriate amount of acetone to get to spec. The entire process is recipe driven based on cylinder sizes and is strictly weight driven and verified. The system is complete with all operator prompts for maintaining a strictly guided operation.

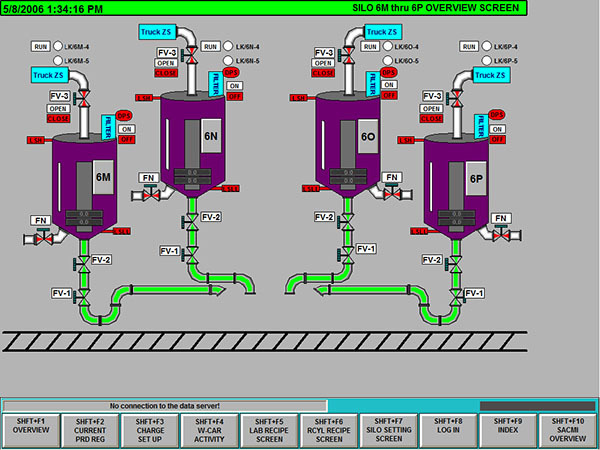

Casting Powders & Mould Fluxes HMI Application

• Stollberg

A total plant control system. All automated control and HMI by CIR. The plant is driven from an SAP Enterprise system that communicates raw material specification, order entry, and recipe to the plat floor. The SAP system in return is the receptor for completed factory orders. The systems, SAP and Factory Floor, operate seamlessly trading data to complete customer orders and maintain inventory of raw and finished goods. Raw material is delivered to the plant and stored in silos. Raw material testing is done and reported to SAP. Orders are mated with recipes and sent to the Factory Floor. The batch car assembles the recipe materials and sends to the post processing spray towers. Finished materials are dry and sent to bagging stations where the products are bagged and palletized. Total mass balances are done daily to compare production with input.

Ceramic Coating Process HMI Application

• Treibacher Schleifmittel USA

This is post processing of the plant’s main grinding and sizing processing of abrasive materials. C-Coat blends wet mixes of ingredients and dries the resulting material into a finished product. Key elements are the control of the gas driven brick lined rotary kiln dryer. Ramp/Soak driven heat up and cool down provide for long kiln life. Carefully controlled dry weight addition on the fly along with Slurry volumetrically controlled pumping.

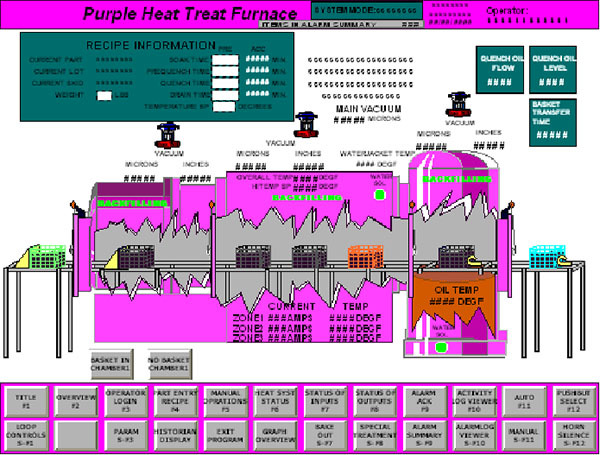

Vacuum Heat Treat HMI Application

• McGard/McCauley

Fully automated "Heat Treat Processing" of the high-quality and major automotive manufacture specified wheel locks. Process is Recipe driven from the HMI and controlled via Programmable Controller, PLC. All heat and cooling is prescribed in the recipe using the industry standard Ramp/Soak profiles. All processes are monitored and data is collected in a Microsoft SQL database. Database retrieval tools were provided to retrieve data by skid and batch and produce temperature trends, recipe information, and alarms that occurred during the process.

Servo Motion Application

• Totally Automated Automotive Aluminum Radiator Assembly

The project had 8 Axis of Allen-Bradley Servo Motion in a Sercos Communication Ring and 10 Axis of Allen-Bradley Variable Speed Drive motion on DeviceNet synchronized with the assembly activity. As a turnkey project we followed the machine to Wisconsin for startup.

Light Curtains and safety relays guard all access to the assembly area. The safety relays made certain that all motor power was safely disconnected during any intrusion into the moving apparatus. While loading parts, the operator could move freely in the zone without tripping a Machine Emergency Stop. However, if the Light Curtain is interrupted during motion, the Emergency Stop would bring the entire machine to a halt.

The HMI was Allen-Bradley PanelView presenting all status and control for the operation.